Everything OEMs should know about designing Rubber Keypads

The Significance of Rubber Keypads: Exactly How They Boost Individual Experience Throughout Different Industries

Rubber keypads are integral components in different markets, contributing substantially to individual experience. Their tactile responses supplies a sense of control and convenience, while their sturdiness guarantees lengthened use. The adjustable nature of these keypads permits for aesthetic enhancements that satisfy consumer choices. Recognizing their applications discloses how these functions translate into customer satisfaction. What certain advantages do rubber keypads offer each sector, and how do they foster brand name loyalty?

Recognizing Rubber Keypads and Their Functionality

Rubber keypads, important parts in lots of electronic devices, offer as the key user interface for customer interaction. Comprised of elastomer products, these keypads provide responsive feedback and sturdiness, making them appropriate for different applications. They contain numerous layers, consisting of a conductive layer that finishes the circuit upon vital activation, guaranteeing trustworthy efficiency. The layout often features raised switches, which facilitate convenience of use and access, specifically in environments where users could put on gloves or have actually limited dexterity.

Rubber keypads are immune to wetness, dust, and chemicals, boosting their durability and integrity in varied settings. Their personalization prospective allows manufacturers to produce one-of-a-kind formats and styles tailored to details user demands. This functionality not just boosts user experience however also enables smooth assimilation throughout devices, strengthening the value of rubber keypads in contemporary technology. Overall, their versatility and practicality make them vital parts in the electronic landscape.

The Role of Rubber Keypads in Customer Electronic Devices

While several parts add to the performance of customer electronics, rubber keypads play an important duty in enhancing customer interaction. These keypads are generally located in devices such as remote controls, smartphones, and gaming controllers, offering responsive responses that boosts the general customer experience. The soft, adaptable nature of rubber keypads permits for comfortable pushing, making them optimal for regular use.

In addition, their longevity and resistance to put on warranty longevity, an essential element for tools subjected to daily handling. Their design can be tailored to accommodate different forms and dimensions, permitting manufacturers to create visually pleasing items that are also practical. Rubber keypads commonly feature water and dirt resistance, making them ideal for varied environments. Ultimately, the combination of rubber keypads in customer electronics not only simplifies communications but also adds to the access and usability of contemporary technology.

Enhancing User Experience in Medical Devices With Rubber Keypads

Rubber keypads can especially improve user experience in clinical tools via their ergonomic style, which promotes comfort throughout extended use. Furthermore, these keypads supply benefits in hygiene and cleanliness, making them appropriate for environments where cleanliness is extremely important. The combination of rubber keypads in clinical innovation offers a chance to boost both functionality and security for health care experts and people alike.

Ergonomic Design Benefits

The combination of ergonomic design in clinical gadgets considerably improves individual experience, particularly with the usage of rubber keypads. These keypads are crafted to satisfy the all-natural shapes of the hand, minimizing stress throughout long term usage. Their tactile responses provides customers with a satisfying feedback, assisting in precise input in high-pressure situations. Rubber keypads typically feature larger, well-spaced tricks that minimize the likelihood of errors, which is vital in clinical setups where accuracy is vital. Additionally, the soft qualities of the rubber material enables comfortable procedure, specifically for individuals who might have dexterity obstacles. On the whole, the ergonomic style of rubber keypads significantly adds to a much more instinctive and user-friendly experience in medical devices.

Health and Cleanliness

The Impact of Rubber Keypads on Automotive Controls

Rubber keypads play a crucial duty in automotive controls by supplying boosted sturdiness and integrity, important for automobiles that withstand various ecological conditions. In addition, their design adds to improved comfort designs and functionality, allowing motorists to interact with controls extra pleasantly and efficiently. The assimilation of rubber keypads go to this site can substantially affect the general customer experience in automobile settings.

Boosted Resilience and Dependability

While many elements in automobile design deal with the stresses of day-to-day usage, rubber keypads stand apart for their remarkable resilience and reliability. These keypads are crafted to endure severe temperatures, dampness, and mechanical wear, making them perfect for different automotive applications. Their resistance to ecological factors assurances regular performance, even in extreme problems. In addition, rubber keypads are less susceptible to cracking or fading compared to conventional products, which enhances their long life. This toughness is important for auto controls, where functionality directly influences safety and customer satisfaction. By preserving a reliable interface gradually, rubber keypads contribute significantly to the published here overall dependability of auto systems, permitting makers to offer a trustworthy experience for vehicle drivers and passengers alike.

Improved Functional Designs and Functionality

A significant benefit of rubber keypads in vehicle controls is their contribution to enhanced ergonomics and functionality. These keypads are made to fit pleasantly within the chauffeur's reach, ensuring that crucial features can be accessed easily and with ease. The tactile comments provided by rubber materials enhances the individual experience, enabling chauffeurs to run controls without diverting their interest from the roadway. Furthermore, the non-slip surface of rubber keypads assures a safe grasp, even in adverse problems. This layout factor to consider lessens the threat of unintended activation, additional promoting security. Rubber Keypads. Finally, rubber keypads enhance the ergonomics of vehicle controls, promoting an extra easy to use environment that eventually adds to more secure driving experiences

Durability and Ecological Resistance of Rubber Keypads

Keypads made from rubber are renowned for their impressive resilience and durability in various ecological problems. These keypads are created to endure extreme temperatures, wetness, and direct exposure to UV light, making them a suitable option for outside and commercial applications. Their intrinsic versatility enables them to soak up shocks and effects, reducing the threat of damage from unintended drops or harsh handling. Furthermore, rubber keypads are immune to oils and chemicals, ensuring durability even in extreme workplace. This toughness converts right into lowered upkeep expenses and less replacements, boosting general user experience. Moreover, their ability to retain capability regardless of direct exposure to dirt and debris makes them appropriate for a myriad of markets, consisting of vehicle, clinical, and consumer electronics. The robust nature of rubber keypads plays an essential function in ensuring dependability and performance, ultimately contributing to user satisfaction across different industries.

Visual and Ergonomic Considerations in Rubber Keypad Layout

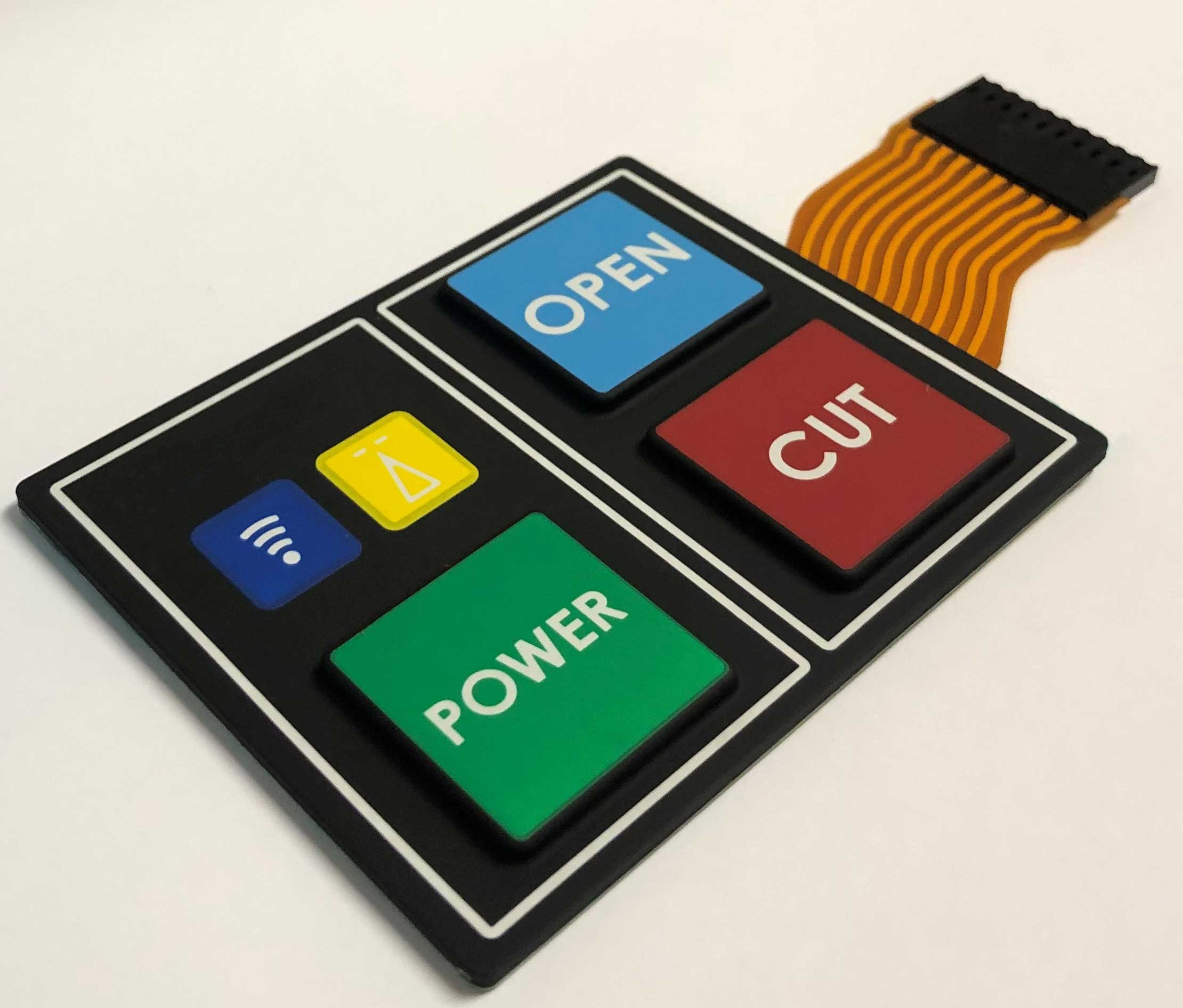

The sturdiness and environmental resistance of rubber keypads supply a strong foundation for their style, but comfort designs and aesthetic appeals also considerably affect individual experience. The visual charm of a rubber keypad can notably affect user interaction; formats, shades, and structures are meticulously taken into consideration to line up with brand identity and consumer choices. An attentively designed keypad not only attracts individuals but additionally boosts performance through instinctive layout.

Functional designs plays an essential duty as well, as the tactile feedback and crucial spacing must fit diverse customer demands. Comfort throughout extended usage is why not try here important, prompting developers to concentrate on the shape, dimension, and positioning of tricks. Attributes like elevated keys or contouring can improve usability, lowering the risk of pressure or discomfort. Inevitably, an equilibrium between visual allure and ergonomic performance guarantees that rubber keypads add favorably to customer fulfillment across different applications and industries.

Often Asked Questions

What Materials Are Frequently Made Use Of in Rubber Keypad Manufacturing?

Common products utilized in rubber keypad manufacturing consist of silicone, polyurethane, and polycarbonate elastomers. These materials provide sturdiness, versatility, and tactile responses, making them appropriate for various applications in digital tools and industrial equipment.

Just How Do Rubber Keypads Contrast to Other Input Devices?

Rubber keypads supply toughness and tactile responses, identifying them from touchscreens and mechanical switches. They give a reliable, weather-resistant input choice, typically favored in commercial settings, while various other devices might lack similar durability and user convenience.

Are Rubber Keypads Customizable for Particular Applications?

Yes, rubber keypads can be customized for certain applications. Producers typically use various shades, shapes, and responsive comments options, enabling customers to customize the keypads to fit their aesthetic and useful requirements efficiently.

What Are Usual Issues With Rubber Keypads Gradually?

Common problems with rubber keypads gradually include deterioration, fading of symbols, lowered responsive feedback, and deterioration as a result of environmental elements such as moisture, temperature level fluctuations, and exposure to chemicals, affecting their performance and toughness.

Just How Are Rubber Keypads Tested for Quality Control?

Rubber keypads undertake extensive screening for high quality assurance, consisting of resilience evaluations, tactile feedback examinations, and environmental resistance checks. These tests ensure efficiency uniformity, longevity, and individual satisfaction throughout different applications and markets, maintaining high requirements.

Rubber keypads are important parts in different markets, adding significantly to individual experience. While many parts add to the performance of consumer electronics, rubber keypads play a critical function in improving individual communication. Rubber keypads can notably improve individual experience in clinical tools via their ergonomic style, which advertises convenience during long term use. The combination of ergonomic layout in medical gadgets significantly enhances individual experience, specifically through the use of rubber keypads. The durability and ecological resistance of rubber keypads supply a solid structure for their style, yet comfort designs and aesthetic appeals also significantly affect individual experience.